Welcome to Camel Matches. We offer the best product

Lab

At Camel Matches, quality begins in the lab. A team of experts conducts rigorous testing aligned with over 30 strict quality standards to ensure each match performs consistently and safely. Every batch is assessed for ignition quality, burn time, and safety, reinforcing the brand’s commitment to excellence.

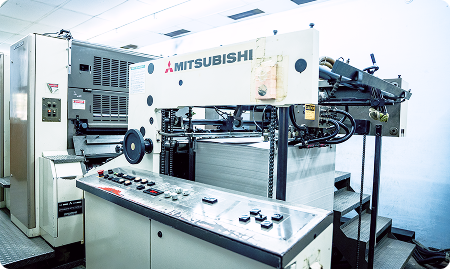

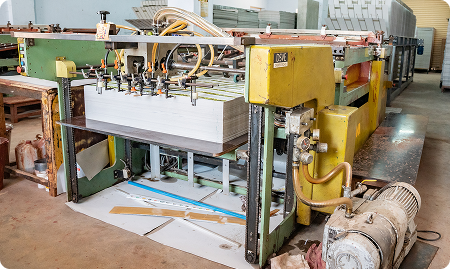

Ayyan’s Infrastructure

For Success

Ayyan Matches takes pride in its robust infrastructure, ensuring exceptional quality and consistent production. Their sprawling 25-acre factory campus houses over 125 specialized machines, allowing for efficient operations. A dedicated workforce of over 20,000 employees meticulously crafts each match, adhering to over 30 stringent quality standards. This commitment to infrastructure empowers Ayyan to deliver unmatched performance and reliability in every single match.

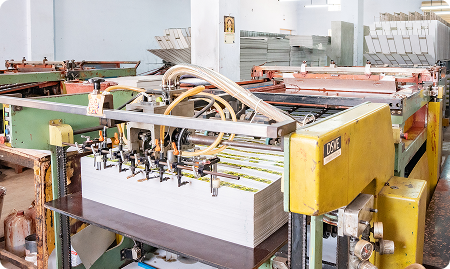

Production

The heart of Camel Matches lies in its state-of-the-art production facility, spread across a vast 25-acre campus. Equipped with over 125 specialized machines, the factory operates with precision and efficiency. More than 20,000 dedicated workers are involved in the meticulous crafting of each matchstick, ensuring high-volume output without compromising quality.

Packaging

Once crafted, every matchbox goes through a systematic and hygienic packaging process. Advanced machinery and manual inspection combine to maintain consistency in branding and box quality. The robust infrastructure allows Camel Matches to deliver neatly packed, durable matchboxes ready for reliable use across markets.